Integrating Vision, Reality, Service to Deliver More as a Contract Manufacturer

CJB Industries installed an automated small bottle packaging line that is purpose-built for markets where small volumes of product are critical to success. The line accommodates totes, drums, and bulk tankers of product to put in bottles sized 4 ounces to 1 liter.

The meaningful implementation of technology into the contract and toll manufacturing process demands a mix of vision and reality while maintaining a service mentality. CJB Industries is forging a path forward through leadership, innovation, and training designed to create and deliver added value for their manufacturing partners.

Leadership focused on innovation and relationships

Recent leadership appointments position CJB Industries to capitalize on technology and digital advancements that make a difference in their customers’ business, while enhancing the customer experience, growing relationships, and elevating their capabilities and services. The team guiding technological advancements is led by Mitchell Tatar, Director of Innovation, while Sims Turner, Vice President of Sales and Business Development, leads the team driving customer relationships and market development.

“CJB Industries is poised to transform our capabilities as a contract and toll manufacturer by tapping into the vast potential of technological advancements,” said Clinton Beeland, Founder and CEO of CJB Companies, parent company of CJB Industries. “We’ve put a high-quality team in place to help guide us, our customers, and future customers through the journey and ensure we’re continuing our service, quality, and safety excellence.”

Turner elaborated, “We are excited for the future while remaining grounded in our core values that have enabled our organization to establish high standards for contract and toll manufacturers. Our customers, our partners, recognize the value we bring to them through our CJB values, or RITES of respect, integrity, trust, excellence, and stewardship. I believe embracing our CJB RITES in each interaction combined with our ability to deploy technology where it makes sense will differentiate us.”

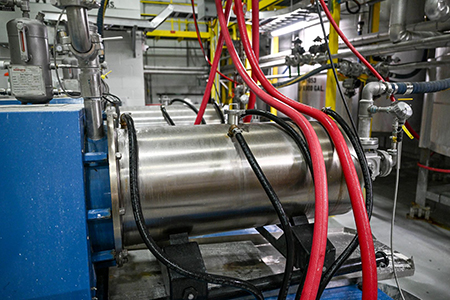

Additional batch tanks expand milling capacity and efficiency to keep product moving through the production process and enable CJB Industries to deliver on time.

Leading technological innovation that delivers added value for partners

Over the past several years, CJB Industries has been actively responding to customer needs and preparing for future technological advancements. They have completed equipment, technology, and facility upgrades, such as the installation of an automated small bottle packaging line, additional batch tanks to expand milling capacity and efficiency, and a 51,500-square-foot expansion to accommodate bulk production, more warehouse space, and upgrades to laboratories and office facilities.

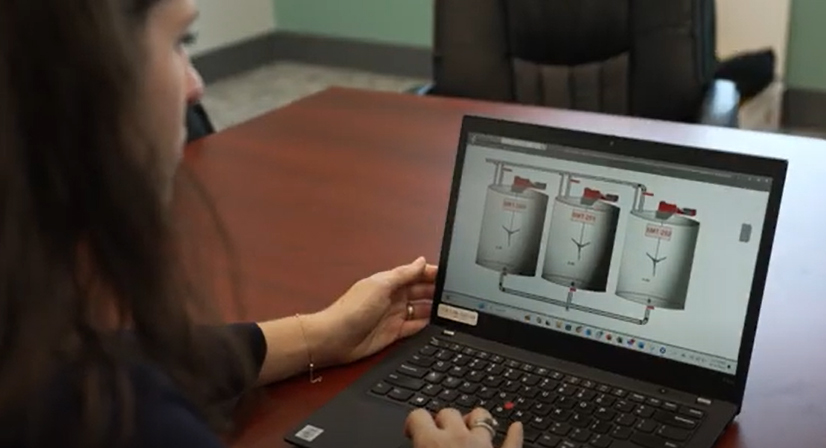

In addition, Tatar and team have tapped into technology to transform operational data across CJB Industries’ three manufacturing plants. With support from Georgia Manufacturing Extension Partnership (GaMEP), they implemented dataPARC to provide real-time data analysis and visualization that enabled them to optimize the manufacturing process. They adopted new quality management software that helped the facilities realize increased productivity by reducing quality concerns, expanding capacity, and communicating more effectively. The team is also in the midst of digitizing packaging and batch sheets to improve quality, efficiency, and production visibility.

Over the next several years, the team will deploy strategic initiatives that use data, AI, and technology to elevate the customer experience while reducing risk and increasing speed. They are focused on developing transformative solutions, impactful digital advancements, innovative technologies and products, and expanded services. The goal is to optimize operational processes and enhance effectiveness for the benefit of their partners.

“We have always been focused on delivering the best product in an efficient manner and on time for our customers. With all the technological advancements, we intend to take a leadership role in deploying technology where it makes sense not just for our business, but also our customers’ business,” Tatar explained. “Our team is unique in its ability to bridge the gap between vision and reality because we’ve been on the operational side of the business. We understand how and where to implement innovations that deliver added value to our customers by streamlining processes, elevating quality controls to ensure project accuracy, and expanding services and capabilities.”

Data software investments helped CJB Industries increase production capacity by 20%, enhance preventive maintenance, and improve quality management.

Training programs designed for safety and customer success

In addition to a focus on innovation, CJB Industries prioritizes safety through training programs, incident analysis, and facility improvements so employees understand the latest standards while delivering products to customers accurately and on time. Their efforts across all three facilities were recognized by the SOCMA 2024 Safety Recognition Program.

“Our safety culture is emphasized to all employees from day one,” explained Sedra Beckman, GSP, PMOSH, Health, Safety and Environmental Manager at CJB Industries. “We believe that by understanding the states that lead to errors and being able to identify critical errors, employees can help reduce the risk of injury.”

The training and innovation teams use data analytics to assess safety reports, evaluate processes, and identify areas for improvement. Insights are transformed into new training material to support education throughout an employee’s career, so they are equipped with the latest information and tools that allow them to maintain the safety culture while providing customers with top-level service and results.

To experience a higher standard in contract and toll manufacturing, contact CJB Industries at 229.293.0800 or [email protected], or visit www.CJBIndustries.com.