Biosynthesis Technology Of Plant Stem Cells Promote The Rapid Development Of Botanical Pesticide Industry

Plants are rich in carbohydrates, proteins, fats and other nutrients, as well as a large number of secondary metabolites. It has a long history of application in medicine, spices, dyes, pigments, pesticides, food additives and other fields [1]. For a long time, plant resources have become one of the important resources of food and medicine for human survival. Plant secondary metabolites are a large class of small molecular organic compounds that are not necessary for growth and development in plants, but play an important role in stress resistance, disease resistance and pest resistance for the plant.

At present, the reported secondary metabolites of plants mainly include alkaloids, flavonoids, aldehydes, lignans, etc., with more than tens of thousands of species. Now, some secondary metabolites have been developed into commercial products with broad social needs and important application value. For example, artemisinin is used for the treatment of dysentery, shikonin is used for antibacterial, vanillin and rose oil are used as spices, pyrethrin, matrine and veratrine are used as pesticides, osthol, carvacrol and berberine have been widely used for the control of agricultural diseases.

With the research of new types of medicinal plants and the investment of advanced technology, more and more new secondary metabolites of medicinal plants with high biological activity have been discovered, and the demand for plant resources is increasing. In addition to wild collection, artificial cultivation of medicinal plants is still the main way to provide raw materials. Artificial cultivation has high requirements on plant seeds, soil, climate conditions, etc. It is easy to be infected with diseases during the cultivation process, and some medicinal plants have long cultivation time and high management costs. At the same time, the contradiction between the cultivation of medicinal plants and the cultivation of crops has become increasingly prominent[1], the supply and demand of highly active plant secondary metabolites is tension [2].

At present, it is an effective way to solve the problem of medicinal plant resources by using plant stem cell bioreaction technology to feed the induced plant single cells in large scale and in vitro to obtain a large number of highly active target metabolites.

1. Concept And Development Of Plant Stem Cells

Plant tissue culture and cell culture began in the second half of the 19th century. On the basis of the cell theory established by Schleiden and Schwann, German plant physiologist Habedandt put forward the famous argument of “Plant Stem Cell Totipotency” in 1902 [3], believing that plant stem cells have the ability to develop into complete plants in vitro. However, it was not until 1934 that White [4] established the first active growing clone using isolated tomato roots that the root culture experiment in vitro was truly successful for the first time. Twenty-three years later, Skoog and Miller [5] found that kinetin can effectively promote cell division and bud regeneration of explants. The most important thing is that high kinetin/auxin ratio induces bud formation and low kinetin/auxin ratio promotes root formation. This discovery laid the foundation for regeneration and cell engineering in plant tissue culture, and unveiled the secret of hormone regulating plant organ regeneration. Muir et al. [6] established the first plant stem cell suspension system using marigold callus. They successfully observed that a single cell can divide into small cell clusters through the method of callus feeding. In 1958, Steward et al. In the same year, German scientist Reinert [8-9] also obtained similar research results. Since then, after more than 50 years of continuous verification by researchers, the totipotency of plant stem cells has been fully verified.

Fig. 1: Plant stem cells of different varieties

2. Plant Stem Cell Bioreaction Technology

Compared with conventional cultivation techniques, plant tissue and cell culture has significant advantages in the production of target secondary metabolites of medicinal plants. [10] Unlike cultivated plants, plant stem cell bioreaction technology uses industrial reactor production system and supporting recovery process, and can realize uninterrupted operation throughout the year with the support of automatic control system. It is not affected by soil environment, climatic conditions, biotic and abiotic stresses. The aseptic environment is controlled during the whole culture cycle, and there is no need to use pesticides to prevent the invasion of diseases, insects and weeds. At the same time, the basic nutrients provided by plant stem cell bioreaction are cheap, and the cost benefit is more significant compared with mammalian, insect and yeast cell culture systems.

As a chassis cell of biosynthesis, plant stem cells have inherent advantages in synthesizing natural metabolites of plant origin. Unlike bacteria, plant stem cells, as eukaryotic systems, have the ability to correctly fold and assemble polymeric proteins. In addition, plant stem cells can carry out post-translational modifications of proteins that rarely occur in many prokaryotes, adding more possibilities for the regulation of biosynthetic pathways. Plant stem cells will not produce bacterial toxins during the biosynthesis of target products, and the synthesis system is more safe. In addition, plant stem cells contain complex inner membrane, which can successfully express the key protease in the process of primary biosynthesis that needs to be located in the plastid system.

Table 1. Comparison of different biosynthetic chassis

| Species | Advantages | Disadvantages |

| Germ | Simple genetic material, easy for genome sequencing, transformation and large-scale culture, rapid growth and mature culture system | It is difficult to achieve post-translational modification, lack of endoplasmic reticulum leads to CYP450 aromatase damage, substrate and product inhibition, and may have bacterial endotoxin |

| Yeast | The genetic material is simple, easy to transform and large-scale culture, growing rapidly, and the culture system is mature | The operation of genetic engineering is complex and lack of post-translational modification |

| Alga | Simple genetic material, easy to scale cultivation, photosynthetic autotrophic, with post-translational modification, and mature culture system | Lack of effective genetic engineering tools and long growth cycle |

| Plant Stem Cells | Easy to scale culture, mature genetic engineering tools, moderate growth rate, post-translational modification, existence of intimal system, and few regulatory problems of genetically engineered cells | The acquisition of stem cells from non-model plants is uncertain, and the metabolic regulation network is less complex |

| Native Plant | There is no need to build a biosynthetic pathway, the work intensity of genetic engineering is low, the toxicity tolerance is large, and the production potential is large | The downstream products are difficult to process, have a long growth cycle and consume a lot of land and other natural resources |

| Chemical Synthesis | Easy to scale production, simple and rapid synthesis | It is difficult to synthesize plant secondary metabolites with polychirality, involving hazardous chemicals, and is not friendly to the environment, which is marked as artificial synthesis |

Plant cell genetic transformation methods are mature and stable. With the development of new gene editing tools, it is no longer difficult to regulate the expression of alien genes. Through the research of metabolic pathway, the key genes and rate-limiting enzymes of the target product biosynthesis route can be genetically operated to improve the target product biosynthesis. Genetic engineering technology can also be used to explore or artificially create new biosynthetic routes to obtain other target metabolites that are not capable of synthesis in the background cell varieties. Combine the advantages of chassis cells with the synthetic ability of target metabolites to significantly increase production. At the same time, through the biological reaction transformation, the precursor material with low value can be converted into the target product with high value. As an effective way to solve the resource problem, plant stem cell bioreaction technology has become one of the important development fields of modern biotechnology.

Fig. 2: Plant stem cell biological reaction

As the chassis of biosynthesis, plant stem cells show their unique advantages. Transgenic or genetically edited engineered cells are not complete plant varieties and face fewer regulatory issues. However, the acquisition of native stem cells from non-model plants is uncertain, and the highly complex metabolic network regulation mechanism also brings unprecedented challenges to the work of biosynthesis.

Table 2. Cases of biocatalytic synthesis of plant stem cells [13]

| Plant Species | Substrate | Outcome | Reaction Type |

| Common tobacco | Linalool | Dihydrolinalool |

Hydroxylation, Glycosylation, Oxidation-reduction |

| Common tobacco | α- Terpinol | Hydroxyterpinol | |

| Common tobacco | t-resveratrol | t-paclitaxel | |

| Catharanthus roseus | warfarin | Warferin alcohol | |

| Catharanthus roseus | Geraniol, Nerol, Carvone | Hydroxyneo-dihydrocarveol | |

| Astasia longa | Carvone | Dihydrocarvone, Isodihydrocarveol | |

| licorice | Papaverine | Papaveritol | |

| Centella Asiatica | Thiocolchicine | Monoglucosyl derivative | |

| Papaver | Silybin | Silybin-7-O- β- D-glucopyranoside | |

| Papaver | Codone | Codeine | |

| Carrot | Codone | Codeine |

3. Bioreaction Technology Of Plant Hairy Roots

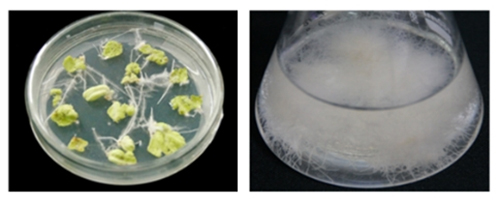

The most commonly used production system in plant material bioreaction plants is stem cell suspension culture. However, under special circumstances, some specific secondary metabolites may not be produced in undifferentiated tissues, or the synthesis of some plant secondary metabolites is highly dependent on specific tissues and organs. Hairy root bioreaction technology provides another solution. The hairy root bioreaction technology is to use Agrobacterium rhizogenes to infect plants to produce hairy roots.

Fig. 3: Bioreaction of plant hairy roots

This technology does not need external growth regulators and additional light sources, and it grows rapidly, has many branches, and the content of specific secondary metabolites is much higher than that of cell suspension culture. The biological reaction of hairy root is also affected by the factors of nutrient composition, inducer, precursor and gene manipulation, and is considered as one of the best raw materials for obtaining plant secondary metabolites.

Table 3. Cases Of Biocatalytic Synthesis Of Plant Hairy Roots

| Plant Species | Substrate | Outcome | Reaction Type |

| Ginseng | Digitalin | Digitoxigenin |

Stearic Acid Esterification, Hydroxylation, Glycosylation, Redox, Methoxylation |

| Common Tobacco | t-resveratrol | t-Pieceatannol, t-Peterostilbene, Piceid | |

| Lobelia | Gallic acid | β- Glucosamine | |

| Kaladana | Umbelliferone | ||

| Polygonum Multiflorum | 1,4-Benzenediol | Arbutin | |

| Wintercherry | Hydroquinone | Arbutin | |

| Tobacco | t-resveratrol | Piceid | |

| Polygonum Multiflorum | Aescinat lactone | Aescinat glycoside | |

| Datura | Hydroxybenzyl alcohol | Gastrodin | |

| Cyanotis Arachnoidea | Artemisinin | Deoxyartemisinin | |

| Angelica Archangelica | Geraniol | Linalool | |

| Angelica Archangelica | Geraniol | Citronellol | |

| Dill | Geraniol | α- Terpineol | |

| Atropa Belladonna | Trimethoxyacetophenone | Trimethoxyphenylethanol | |

| Common Tobacco | t-resveratrol | t-Peterostilbene |

At present, the use of hairy root bioreaction technology as a suitable material for biosynthesis and transformation is gaining advantages over plant stem cell culture bioreaction. They have many advantages, including biochemical and genetic stability, low sensitivity to changes in culture conditions, enzyme potential very similar to parent plants and low cost.

4. Development Status And Research Progress Of Plant Stem Cell Culture

- Global Industrialization Status

Over the years, great progress has been made in the production of medicinal ingredients through plant stem cell bioreaction technology. At present, there are more than 400 kinds of plants that have been studied and can produce more than 600 kinds of primary and secondary metabolic components, of which a considerable part has medicinal value, and some have successfully achieved industrial production. As early as 1956, Routier and Nickell in the United States proposed a patent for the synthesis of natural products from plant stem cell culture [10]. In 1983, Mitsui Petrochemical Company of Japan announced the industrial production of shikonin as a dye and drug. In addition, the industrial production of digoxin from rehmannia cells culture through biotransformation, coptis chinensis cell culture to produce coptidine, and ginseng root culture to produce ginsenoside has been realized. Other cell cultures, such as catharanthus roseus and perilla frutescens, also reached the pilot level [12]. Through the stem cell culture technology of Taxus chinensis, the taxol biosynthesis reached 1045mg/L, which was more than 298 times higher than the parent plant. The total glycosides synthesis of Centella asiatica reached 1670mg/g DW, which has fully met the needs of industrialization. Belgium Green2chem and France Naturex and other companies have actively used the plant hairy root biological reaction technology, and successfully achieved the biosynthesis of more than 20 high-value medicinal ingredients, such as nicotine, cilimarin, paclitaxel, quinine, and forskoline. In China, Newland Biology has studied plant cell microbubbles as drug delivery media. By 2018, the company has completed angel round financing and has built plant stem cell biological reaction equipment of more than tons. At the beginning of 2022, American Phyton invested 3 billion yuan to start the construction of PCF plant stem cell biological reaction “super factory” in Xuzhou. After completion, the expected sales revenue will reach 7 billion yuan.

- Biosynthesis Boosts The Rapid Development Of Botanical Pesticide Industry

A few steps can lead to a thousand miles. Chengdu Newsun Crop Science Co., Ltd. (hereinafter referred to as “Newsun”) has been focusing on the development of green agriculture for more than 20 years since its establishment, and is a leading botanical bio-pesticide technology enterprise in the industry. The active ingredients of botanical pesticides are mostly natural and highly active secondary metabolites, which have the characteristics of fast degradation, good environmental compatibility, low residue, etc., which are in line with the current trend of environmental protection development, and the market demand continues to grow. However, with the advancement of industrialization, the problem of medicinal plant resources will soon become a technical bottleneck in the application of highly active natural products.

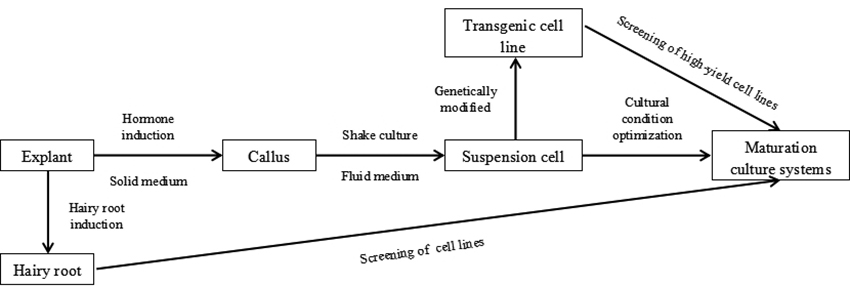

Fig.4: Basic route of plant stem cell bioreaction technology

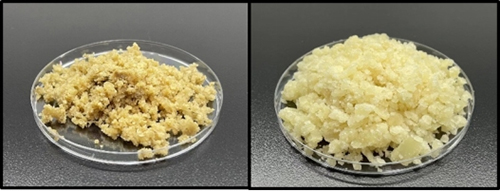

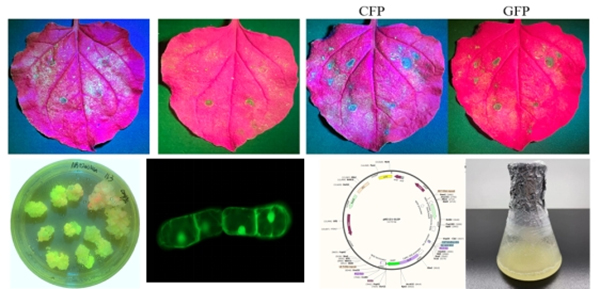

Newsun has made important progress in the research of plant stem cell bioreaction technology through callus induction, plant stem cell suspension culture, hairy root induction and other plant stem cell culture technologies.

Fig. 5: Phased results of biological response of genetically engineered plant stem cells

Newsun has obtained more than 10 kinds of plant chassis cell materials with potential for biosynthesis development through the plant tissue stem cell induction technology. After the optimization of biological reaction conditions, the yield of stem cells has reached 550g/L. Through genetic engineering technology, the heterologous expression of the target metabolite chassis was successfully achieved, and the reconstruction of key genes of metabolic pathway of multiple engineering cells was completed. And successfully achieved the research of target metabolite biosynthesis pilot technology. It has laid a solid foundation for advancing the technical goal of industrialization of target natural product varieties.

5. Prospect Of Plant Stem Cell Bioreaction Technology

The long-term blind collection of rare medicinal plants has led to the destruction of the ecological environment. Many wild plants are endangered. It is difficult to introduce plants in some special ecological environments. Plants that can be introduced and cultivated need to occupy a large amount of farmland. Under the restriction of the increasingly reduced area of farmland and the guarantee of the red line of 1.8 billion mu (1ha = 15mu) of farmland in China, the large-scale cultivation of medicinal plants is seriously restricted. In addition, artificial cultivation is restricted by environmental factors. The content of target secondary metabolites in natural plants is too low, and the composition is complex, which creates a high development cost barrier for industrial utilization. Due to the complex structure of natural highly active pharmaceutical products and the large number of chiral centers, the traditional chemical synthesis technology has been unable to meet the needs of production technology. In the face of many of the above problems, scientific workers have great social significance to produce useful secondary metabolites [14-16] by exploring a large number of cultivation technologies of higher plant stem cells and organs.

According to The Analysis Of The Current Situation Of Competition In China’s Botanical Pesticide Industry And The Research Report On Enterprise Investment Strategies, China is a major producer and user of pesticides in the world, while the proportion of biological pesticides (including agricultural antibiotics) in the total amount of pesticides is less than 12.5%, far below the international average level. Bio-pesticides are supported by national policies, in line with the current trend of environmental protection consumption, and the market growth is fast. As the key species of biological pesticides, botanical pesticides have broad prospects for development.

Chengdu Newsun, as a bio-pesticide technology enterprise engaged in the research and development of original biotechnology, is committed to solving the bottleneck of the industrialization of botanical pesticides through the innovative breakthrough of plant stem cell biological reaction technology, and making contributions to the protection of the ecological environment and the promotion of agricultural green development. In the future, Newsun will continue to take crops as the scientific research direction, continue to improve the control effect and reduce the use-cost of botanical pesticides, and promote the rapid development of botanical pesticide industry.

Newsun Crop Science’s website: http://www.cdxzy.com

E-mail: [email protected]

Reference:

[1] Wang Wenlan, Huang Xianrong, Zhang Liping RESEARCH PROGRESS IN FERMENTATION CULTURE OF MEDICINAL PLANT STEM CELLS [J] Journal of Practical Medicine, 20070724 (07)

[2] Hu Shanqun, Liang Rudai, Li Tong, etc RESEARCH PROGRESS IN SUSPENSION CELL CULTURE TECHNOLOGY OF MEDICINAL PLANTS [J] Seed Technology, 2021, 18 (0007)

[3] Haberlandt G. Culturversuche mit isolierten Pflanzenzellen. Akad Wiss Wien Math-naturw Classe, 1902, 61: 1–23.

[4] White P R. Potentially unlimited growth of excised tomato root tipS in a liquid medium[J]. Plant physiology. 1934, 9: 585-600.

[5] Skoog F, Miller C O. Chemical regulation of growth and organ formation in plant tissues cultured in vitro. Symp Soc Exp Biol, 1957, 11:118–130.

[6] Muir W H, Hildebrandt A C, Riker A J. Plant tissue cultures produced from single isolated cells. Science, 1954, 119: 877–878.

[7] Steward F C, Mapes M O, Mears K. Growth and organized development of cultured cells. II. Organization in cultures grown from freely suspended cell. Am J Bot, 1958, 45: 705–708.

[8] Reinert J. Morphogenese und ihre kontrolle an gewebekulturen aus carotten. Naturwissenschaften, 1958, 45: 344–345.

[9] Reinert J. Über die kontrolle der morphogenese und die induktion von adventivembryonen an gewebekulturen aus karotten. Planta, 1959, 53: 318–333.

[10] Li Sheng, Li Wei PRINCIPLES AND TECHNIQUES OF PLANT TISSUE CULTURE [M] Beijing: Chemical Industry Press, 2007, 10

[11] Luo Kai, Hu Tingzhang, Luo Jianping, RESEARCH PROGRESS IN PRODUCTION OF SECONDARY METABOLITES BY PLANT STEM CELL CULTURE [J] Shizhen Guoyi Guoyao, 2007, 18 (10)

[12] Yu Fang ESTABLISHMENT OF CELL CULTURE SYSTEM OF CAMPTOTHECA ACUMINATA AND BIOSYNTHESIS AND PROCESS REGULATION OF CAMPTOTHECIN A AND B [D] Dalian University of Technology, 2005

[13]Abdulhafiz Ferid, Mohammed Arifullah, Reduan Mohd Farhan Hanif, et al. Plant cell culture technologies: A promising alternatives to produce high-value secondary metabolites[J]. Arabian Journal of Chemistry, 2022, 104161.

[14]Baebler S, CamIoh M, Kovac M, et al. Jasmonic acid stimulates lates taxane production in cell suspension culture of yew.P1anta Med, 2002, 68: 475.

[15] Dai Jungui LOOKING FOR THE BIOTECHNOLOGICAL RESEARCH PROGRESS OF THE WORLD’S TRADITIONAL CHINESE MEDICINE. Capital Medicine, 2001, 8 (5): 4.11

[16] Godian THE ROLE OF BIOTECHNOLOGY IN THE MODERNIZATION OF TRADITIONAL CHINESE MEDICINE Foreign Medicines and Botanicals, 1998, 13 (6): 257